Military Antenna Conversion Vs. 3.0

Updated May 1, 2007

This is my new and improved experimental updated version on how to do this conversion.

I started out with an ICOM AH-2b 8' whip antenna which worked great until I closed my garage door on it. The spring took a set that I couldn't fix. ICOM refused to sell me a spring. I said I'd be damned if I was going to spend 300 bucks because I needed a spring. I decided to make something that would be high quality, last and be repairable.

The ICOM antenna has a real nice thin tapered Stainless steel whip and attachment point. It allows me to stow the antenna bent over behind my truck. I have to be able to drive into my garage so the antenna can't stick up. In fact ICOM does sell replacement whips. My thinking was to adapt the ICOM whip assembly to some kind of new spring. I tried a heavy duty spring from Radio shack on the ICOM mount and that was a joke. Since I was already using a Military HMMWV antenna mount for the ICOM I started looking at surplus antennas. I found these really nice high quality MX-6707 base and AS-1729 whip military antennas that were made to fit in my existing mount. They have really heavy duty springs and are built like a tank. You can get the base for 85.00 at Fair Radio Sales. The antenna consists of four parts. The antenna, spring, top case and bottom case. The upper antenna ($15), lower antenna ($18), tie down ($8) and vehicle mount (new for $20).

Just a note. One of my readers is running stock MX6707 bases with the military green whips on 2m and 6m. He said that you can acheive a good match by turning the dial on the bottom of the base.

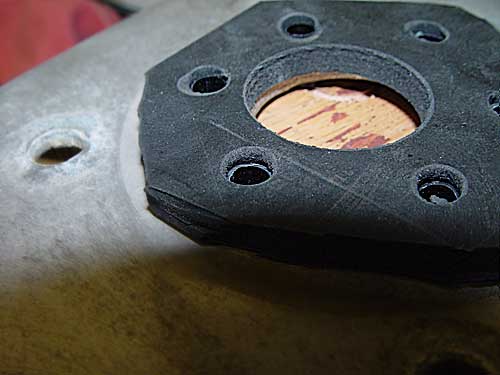

The problem I was having is that the plastic bases kept cracking every 2 years. Even the last one that I has filled with epoxy. This time I removed the spring from the military base and bolted it directly to the plate I originally made for the Icom antenna.

The whip mount is screwed directly into the top of the spring. Because the way the whip mount is machined, the spring is actually feeding the antenna and is hot. That meant I had to insulate the spring from the grounded aluminum mount. I used nylon bushings (shoulder washers) and a thick piece of rubber. I fed the antenna through one of the 1/4" bolts holding the spring to the base. The little wire hanging down the center is the old military feed wire. I capped it off so it wouldn't touch a ground.

Because the spring and it's black base are hot and the aluminum mounting plate is ground I'm concerned that I have created a capacitance between the two. It's possible that the spring itself is an inductor if the paint is insulating the windings. This will effect how the antenna tunes.

With the engine off running on battery power on my first try with my SGC auto tuner I was able to acheive a low (less than 2) SWR on 10, 20 and 40 meters. I could not achieve an acceptable SWR on 17. Further testing showed that the range of frequencies between 16.1 Mhz and 18.3 Mhz would not tune (infinite swr). This setup with the exact same whip straight through used to work fine at all the covered frequencies. With the engine on I was able to tune everything. I haven't figured out what's happening yet.