Eaton Electric Lockers

Detroit Locker Article

Auburn Locker Article

Updated April 19, 2016

Note: Auburn now has an electrical locker for the H1.

Note: Auburn now has an electrical locker for the H1.

In 1999 AMG was mandated by law to put ABS on all the Hummers. For technical reasons they couldn't use the high bias ratio Torsen 1 Differentials (4.45 to 1) with ABS (read the article on Torsens). The high bias torsen diffs are a major feature of the Hummer and are still installed on all military Hmmwv's. This meant that it is nearly impossible to break torque modulate (BTM) a newer truck. BTM locks the axles and stops wheels with no traction from spinning. The down side of BTM brake torqueing is that it places a tremendous strain on the drive train.

All the trucks built since 1999 have TT4 traction control and lower bias 1.6:1 or 1.7:1 Torsens 2's. The TT4 is good in many situations but not optimal for serious off road rock crawling. In 2002 AMG did increase the bias ratio of the Hummer diffs to around 2.5:1 or 3.0:1 which is enough to BTM a little.

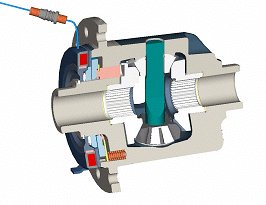

In response to customer dissatisfaction with TT4 and a desire to make the Hummer even better, AMG now offers The Eaton Electrical Locker in the rear of the 2003 Hummers and in the front and rear of the 2004's equipped with the adventure package. The locker has many of the benefits of the Torsen without the drive line stress and leaves the TT4 active to boot. The Eaton diff is a full electrical locker with an integral limited slip (posi traction) clutch pack. It's the best of both worlds. There is a small $174.00 interface computer that presently works with the rears that checks speed (over 30 mph) and tcase position to ensure that it's safe to let the lockers engage.

AM General says that the lockers disengage after 3 minutes of use. If you exceed 15 mph they also disengage. They only work in Low lock.

Note: AMG offered the Detroit in the Hummer in 1997 but I don't know of anyone that had a factory truck with one. Detroits are now popular in the rear.

There are always trade-offs. The higher bias torsens (pre 99) will dynamically deliver torque to the wheel with the most traction without doing anything. It will do this within it's bias ratio which is 4.45 to 1 on pre 1999 trucks. When the difference in traction between left and right is greater then the bias ratio you can fool the Torsen by applying the brake. This is called Brake Throttle Modulation (BTM). This gives you good drivability in many situations without having to add any new hardware to the truck. The downside is that BTM can use tons of engine power (better used for climbing) and twists the drive train which causes brakes, halfshafts, driveshafts, transfer cases and diffs to break, stretch and wear.

A locker is either on or off. You manually turn on a locker when the conditions are such that you know you are going to loose traction like when you are approaching a difficult climb. A locker mechanically connects the right and left wheels so it is impossible for one to spin while the other is on a good traction surface. With a front and rear locker you get true 4wd. With a locker you don't need to BTM which means that you don't have to touch the brakes. Once you have traversed the obstacle you turn the lockers off. Because the lockers connect the right and left wheels the steering capability of the truck is greatly curtailed with the front lockers on. That's why AMG has incorporated safety measures to ensure that you can't engage the lockers unless the truck is in 4L moving at a slow speed.

October 10, 2004

Many people have been waiting 2 years for AMG to release the Eaton electrical locker retro fit. AMG Part number: 5745798 price $4594.92. However the spec time for installation is 11.8 hours which mostly involves replacing 2 diffs. The installed price at a dealer is going to be around 6000.00.

From the bulletin: they are only available for 1999-200X. This is probably because the electronic switch interface to ensure that the lockers are not engaged at the wrong time was designed for the newer computers (ecm). Another minor factor is that the differential gear ratio goes from 2.73:1 to 2.56:1 in 1998. If you are replacing both diffs on an older turbo diesel truck the ratio change won't make much of a difference. If you have a NA diesel or a gas truck the change in ratio will have an effect on the driveability. You will have to recalibrate your speedometer and possibly make a change in the ecm programming it you have a pre 98 turbo diesel.

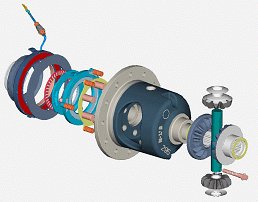

The Kit includes: front and rear Diffs. Control modules, switches, wiring /indicator light assembly, and all the wiring hardware and installation instructions.

These lockers require AMG Synthetic Gear Lube 75W-90 with friction modifier built in. No need to add anything else. That gear lube is made by Cognis for AMG and is the only recommended fluid for the H1 with Eaton. It's around $20/quart. You can use regular gear oil with GM friction modifier (GM#1052358 fiction modifier) or any other synthetic gear lube if you want. If you don't use the correct lubricant the diff won't slip in a turn producing a binding noise.

The whole Eaton diff assembly as shown costs $2,200 each axle. You will need a connector cable ($43.00 ea), 2 output seals ($4.00 ea), 12 half-shaft bolts with nord washers (.70 ea) for each diff. You also will need a couple of bottles of the special GM friction modifier ( GM limited-slip axle additive 1052358) to mix in with the lubricant. Otherwise you will experience gear binding.

The lockers draw about 4 amps each and there is no polarity when you wire them up.

Your only full locker alternative is to get ARB air lockers which have problems of their own if they are not installed correctly. The ARB's are open diff's when not engaged. Another option is to go with a Detroit locker on the rear

These diffs install exactly the same as a stock Hummer diff with the addition of the added electrics. One known issue is the need for more friction modifier ( GM limited-slip axle additive 1052358) to prevent binding in the clutch pack. They are also having some issues with the ball ramps in the locker not returning to full unlock. After the lockers are installed don't play around spinning the front or rear wheel pairs in different directions. This is not a situation a vehicle will ever be in and may cause the lockers to jam and not return to full unlock.

According to John Ward at AMG, if you want to test their operation you must turn the wheel all the way until the locker goes to it's fully locked position. Turn it hard until you can't to ensure it's all the way locked. If you turn it one direction and don't lock it and then turn it another direction you could get the locking mechanism jammed up. You may be able to un jam it by backing the truck up 30 feet.

According to John Ward at AMG, if you want to test their operation you must turn the wheel all the way until the locker goes to it's fully locked position. Turn it hard until you can't to ensure it's all the way locked. If you turn it one direction and don't lock it and then turn it another direction you could get the locking mechanism jammed up. You may be able to un jam it by backing the truck up 30 feet.

Installation Notes:

Yes the diff stubs have to come off. The bolts holding the differential housing are too long to get out without pulling them, and in looking at putting the new one in a bolt short enough to clear is too short for a good grab.

Three suggestions that I have so far for anyone else changing their diffs are:

1. Both differentials will come out without removing the calipers from the truck. Just remove the two bolts tying the caliper mounting bracket to the differential. I then zip tied the calipers to the frame and body and even though it is tight especially in the rear thanks to the added width of the parking brake assembly the differential came right out and it saves all of the screwing around with bleeding the brakes unless you are about due for a fluid change anyway.

2. Although it looks like the rear differential will clear and come out very easily I had to remove the 3 angle brackets that are used for mounting the driveline protection. I kept hitting on the one in the center.

3. this is a good time to do a brake service. I'd replace the pads at a minimum.

The only new suggestion that I have would be to remove the caliper mounting brackets from the differentials while they are still in the truck and wait to put them back on until the differentials are back in the truck. Make sure you use locktite Red and torque the bolts to 150 ft lbs.